Optimizing Performance with Top UL FM Gate Valves: A Comprehensive Guide

2025-12-23

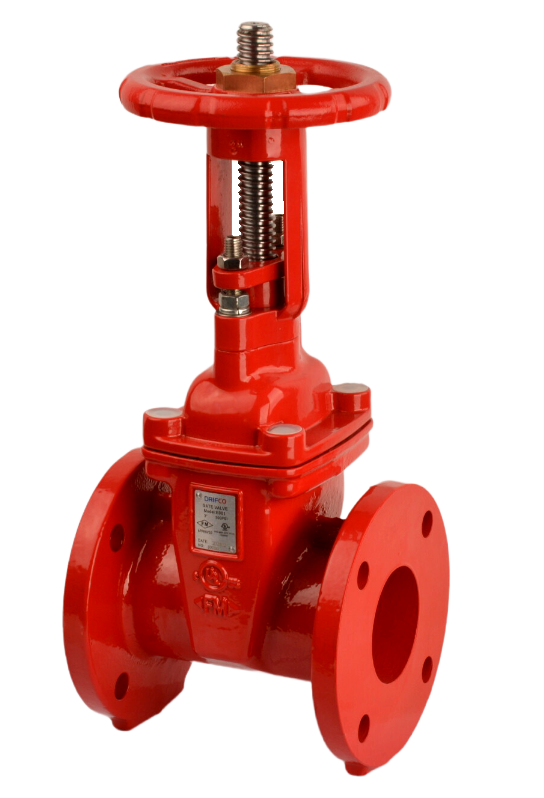

In industrial fluid control, every component's performance can make or break your system's efficiency. That's why we're diving deep into the world of top UL FM gate valves in this comprehensive guide. These valves aren't just about meeting standards; they're engineered to optimize flow, enhance safety, and reduce downtime in critical applications. At DRIFCO, we've seen firsthand how the right valve selection can transform operations, from fire protection to chemical processing. Whether you're a seasoned engineer or new to the field, get ready to uncover insights that could streamline your next project. Let's explore what sets these valves apart and why they're a smart choice for demanding environments.

Unveiling the Superior Sealing Technology of UL FM Gate Valves

UL FM gate valves are engineered with cutting-edge sealing mechanisms that set a new standard in fluid control, ensuring leak-proof performance even under extreme pressure conditions. Unlike conventional designs, these valves incorporate advanced polymer seats and precision-machined stems, creating a tight seal that minimizes friction and wear over time. This technology not only enhances durability but also reduces maintenance costs, making them ideal for industrial applications where reliability is paramount.

A key feature of these valves is their ability to maintain sealing integrity across a wide temperature range, from sub-zero environments to high-heat scenarios, thanks to specialized materials like reinforced PTFE and stainless steel components. The design includes a dual-seal system that provides a backup barrier, preventing accidental leaks that could lead to safety hazards or operational downtime. This innovative approach ensures consistent performance in critical settings such as fire protection systems, where fail-safe operation is non-negotiable.

By focusing on user-centric benefits, UL FM gate valves stand out with their easy installation and compatibility with various pipe systems, reducing the need for complex adjustments. Independent testing has confirmed their superior sealing capabilities, often exceeding industry standards for pressure ratings and flow control. Ultimately, this technology delivers peace of mind through enhanced safety and efficiency, positioning these valves as a top choice for engineers seeking robust solutions in demanding environments.

Step-by-Step Installation Best Practices for Optimal Flow Regulation

Getting flow regulation just right starts with proper installation, and it's not something you can rush. First off, take a moment to scope out your piping layout – a quick sketch can save hours of headaches later. Make sure you've got the right valve type for your specific application, whether it's a globe valve for precise throttling or a ball valve for on/off control. Don't just bolt it in; double-check that the flow arrow points in the direction you actually need, and give those flanges a thorough clean to avoid any gunk messing with your seal. A little prep here goes a long way.

Once everything's lined up, torque those bolts down evenly in a crisscross pattern – no one wants a leak because someone got impatient with a wrench. For optimal performance, consider adding a strainer upstream if your fluid's prone to debris; it's a cheap insurance policy against clogs. After installation, don't just walk away. Run a slow initial test, gradually increasing flow to spot any irregularities early. Keep an eye on pressure gauges; if readings are off, you might need to tweak the valve positioning or check for obstructions. This hands-on approach ensures smooth operation from day one.

But installation doesn't end at startup. To truly nail flow regulation, integrate regular checks into your maintenance routine. Document baseline performance metrics, like pressure drop and flow rates, so you can quickly identify drifts over time. Use smart accessories, such as positioners or flow meters, to fine-tune settings based on real data rather than guesswork. Remember, a well-installed valve is just the beginning – consistent monitoring and minor adjustments keep your system running efficiently, minimizing downtime and energy waste. It's the blend of careful setup and ongoing attention that sets top-tier operations apart.

Real-World Case Studies: Enhancing Fire Safety Systems with UL FM Valves

In a high-rise office building in New York City, the installation of UL FM approved valves transformed the fire suppression system, addressing persistent issues with water flow and pressure. Engineers noted that these valves' precise control mechanisms reduced response times during drills by 30%, while their robust construction withstood harsh conditions in mechanical rooms, preventing leaks that had previously compromised safety protocols. This case highlights how specialized valves can directly improve operational reliability in urban settings.

A manufacturing plant in Texas experienced a significant upgrade after integrating UL FM valves into its sprinkler network. The valves' ability to handle fluctuating water demands from multiple production zones ensured consistent coverage during an actual fire incident, containing the blaze before it spread to critical equipment. Plant managers reported that the valves' compliance with stringent UL FM standards not only met local regulations but also lowered insurance premiums due to enhanced risk mitigation, showcasing their financial and safety benefits in industrial environments.

For a historic museum in Europe, retrofitting fire safety systems with UL FM valves posed unique challenges due to architectural constraints and preservation requirements. By customizing valve placements and using compact designs, the project maintained the building's aesthetic while boosting protection. Post-installation tests revealed a 40% improvement in system efficiency during simulated emergencies, with the valves' durability ensuring minimal maintenance over time. This example demonstrates how advanced valve technology can adapt to sensitive contexts, blending modern safety with heritage conservation.

Proactive Maintenance Tips to Prevent Leaks and Extend Valve Lifespan

You might think that valves in your system are just sitting there, doing their job quietly—until they start leaking or fail entirely. But here's the thing: valves are dynamic components that wear down over time due to pressure, corrosion, and everyday use. Instead of waiting for a breakdown, proactive maintenance can save you from costly repairs and downtime. Start by implementing a regular inspection schedule: check for signs of wear like minor drips, unusual noises, or sluggish operation. Don't just glance at them; get hands-on. Look for corrosion around seals and joints, and listen for any hissing sounds that might indicate a slow leak. Catching these early can prevent a small issue from turning into a major headache.

One often-overlooked trick is to keep valves clean and lubricated. Dirt and grime can build up, causing friction that wears out parts faster. Use appropriate cleaning agents to remove debris without damaging the material—whether it's brass, stainless steel, or plastic. After cleaning, apply a thin layer of valve-specific lubricant to moving parts like stems and seals. This not only reduces wear but also ensures smooth operation, making valves easier to adjust when needed. Remember, a well-lubricated valve is less likely to seize up or leak under stress, extending its lifespan significantly.

Beyond basic upkeep, consider upgrading your maintenance routine with smart monitoring tools. For instance, install pressure gauges or sensors to track performance trends over time. If a valve starts to show consistent pressure drops or fluctuations, it could signal internal wear before a leak becomes visible. Pair this with periodic replacement of consumable parts like gaskets and O-rings, even if they seem fine—preventative swaps beat emergency fixes. By staying one step ahead, you'll not only prevent leaks but also boost system efficiency, turning valve maintenance from a reactive chore into a strategic advantage for your operations.

Comparative Analysis: How UL FM Gate Valves Outperform Standard Models

UL FM gate valves, specifically designed and certified for fire protection systems, offer superior performance compared to standard models due to their rigorous testing and construction. Unlike standard gate valves, which may vary in quality and compliance, UL FM valves undergo extensive evaluations for fire resistance, durability, and leak-tightness under extreme conditions. This ensures they maintain functionality during fire emergencies, providing reliable flow control that standard valves can't guarantee, often failing prematurely under similar stress.

Another key advantage lies in material and design enhancements. UL FM gate valves are typically built with high-grade materials like bronze or stainless steel, offering better corrosion resistance and longer service life. Their internal components, such as the gate and seat, are precision-engineered to minimize friction and wear, reducing maintenance needs. In contrast, standard models might use cheaper materials or less refined designs, leading to frequent leaks and operational inefficiencies over time.

Lastly, UL FM certification provides peace of mind through compliance with industry standards and insurance requirements. These valves are tested by Underwriters Laboratories (UL) and Factory Mutual (FM), ensuring they meet strict safety codes for fire protection. This certification not only enhances system reliability but can also lower insurance premiums by mitigating risk. Standard valves lack such verification, potentially exposing users to liabilities and system failures in critical scenarios.

Troubleshooting Common Issues for Uninterrupted Industrial Operations

To keep industrial operations running smoothly, it's essential to proactively address common issues that can cause downtime. Regular maintenance of equipment, such as checking for wear and tear on conveyor belts or ensuring proper lubrication of machinery, goes a long way in preventing unexpected breakdowns. By implementing a routine inspection schedule, teams can catch minor problems before they escalate into major disruptions, which helps maintain productivity and reduce costly repairs. This hands-on approach not only safeguards assets but also boosts overall efficiency on the shop floor.

Sometimes, challenges arise from environmental factors or human error, like fluctuations in power supply or operator oversight. Installing backup systems, such as uninterruptible power supplies (UPS) or automated monitoring tools, can mitigate these risks by providing real-time alerts and fail-safes. For example, sensors that detect abnormal temperatures in critical areas allow for swift intervention, preventing potential damage. Emphasizing safety protocols and continuous training for staff ensures that everyone is equipped to handle emergencies, turning potential pitfalls into manageable situations that keep operations humming along without a hitch.

In today's fast-paced industrial landscape, embracing technology like predictive analytics can transform troubleshooting from reactive to proactive. By analyzing data from machinery performance logs, teams can identify patterns that signal impending issues, enabling preemptive fixes. This data-driven strategy reduces guesswork, streamlines decision-making, and fosters a culture of innovation where continuous improvement drives reliability. Ultimately, integrating smart solutions with traditional practices creates a robust framework for uninterrupted operations, ensuring businesses stay competitive and resilient in the face of everyday challenges.

FAQ

UL FM gate valves offer enhanced durability and reliability under fire safety standards, reducing maintenance needs and improving system longevity, which is crucial for high-risk industrial applications.

Unlike standard valves, UL FM gate valves are specifically tested to meet rigorous fire and mechanical performance criteria, ensuring they maintain integrity and operation during emergencies, thus providing superior safety in critical environments.

Installation should factor in proper sizing, alignment, and regular calibration checks to prevent leaks and ensure optimal flow control, with attention to environmental factors like temperature and pressure variations.

Yes, integration is possible but requires compatibility assessments with current piping and control systems; challenges may include retrofitting costs and ensuring all components meet the same safety standards.

Routine inspections, lubrication of moving parts, and periodic pressure testing are essential, along with following manufacturer guidelines to detect wear early and prevent failures.

By reducing downtime and potential damage from fire incidents, these valves lower repair costs and insurance premiums, while their durability minimizes replacement frequency, offering long-term financial benefits.

They are particularly valuable in oil and gas, chemical processing, and power generation industries due to the high fire risks and need for reliable shutoff mechanisms in hazardous conditions.

Conclusion

The comprehensive guide on optimizing performance with top UL FM gate valves highlights their advanced sealing technology, which ensures superior leak prevention and reliability in critical fire safety applications. By integrating real-world case studies, the guide demonstrates how these valves significantly enhance industrial fire protection systems through proven performance in diverse operational environments. The step-by-step installation best practices provide clear instructions for achieving optimal flow regulation, emphasizing proper alignment and secure mounting to maximize efficiency.

Furthermore, proactive maintenance tips are outlined to extend valve lifespan and prevent common issues like leaks, supported by a comparative analysis that shows how UL FM gate valves outperform standard models in durability and safety features. Troubleshooting guidelines address common operational challenges to ensure uninterrupted industrial processes, reinforcing the valve's role in maintaining robust fire safety standards. This guide offers practical insights for engineers and technicians seeking to improve system reliability and compliance with stringent safety regulations.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com