A Beginner’s Guide to PCB Assembly – Understanding the Basics

2025-05-14

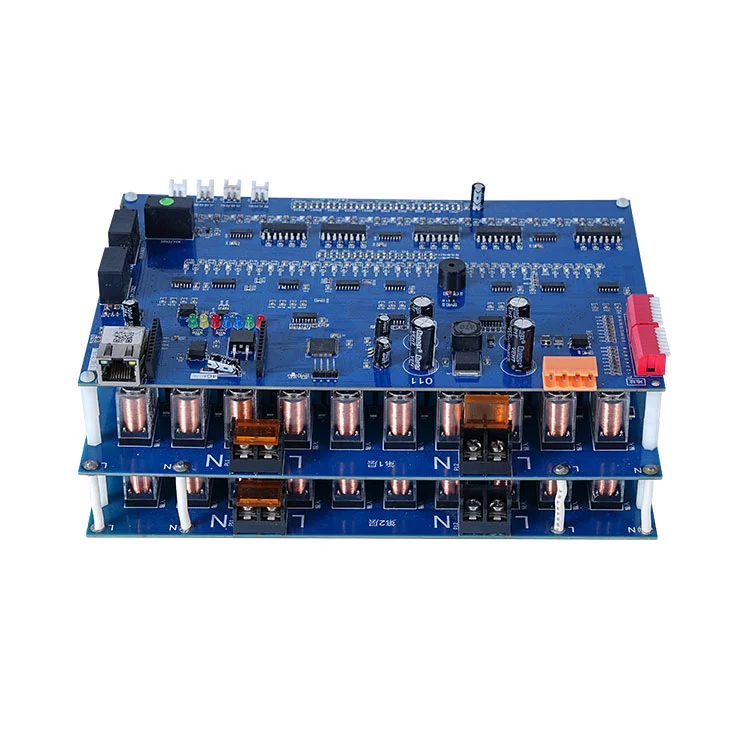

Printed Circuit Board (PCB) Assembly is a crucial step in the electronics manufacturing process, where components are mounted and soldered onto a PCB to create a functioning electronic device. Whether you're a student, hobbyist, or a business exploring electronics production, understanding the basics of PCB assembly can help you make informed decisions.

What is PCB Assembly?

PCB assembly (PCBA) involves placing electronic components such as resistors, capacitors, microcontrollers, and connectors onto a blank circuit board. These boards are designed with conductive pathways etched from copper sheets to connect the components.

Key Steps in PCB Assembly

1. Solder Paste Application

A stencil is used to apply solder paste to the areas where components will be mounted.

2. Pick and Place

Automated machines accurately place surface-mount devices (SMDs) onto the board.

3. Reflow Soldering

The board is passed through a reflow oven, melting the solder paste and securing the components.

4. Inspection and Quality Control

Techniques like automated optical inspection (AOI) and X-ray scanning check for defects.

5. Through-Hole Component Insertion (if needed)

Some boards still require manual or wave soldering for components with leads.

6. Final Testing

Functional tests ensure that the assembled board performs as expected.

Why PCB Assembly Matters

Without proper assembly, even a well-designed PCB won’t function. High-quality assembly ensures electrical reliability, product longevity, and safety. Errors like misaligned components, cold solder joints, or shorts can lead to failures or even dangerous malfunctions.

Final Thoughts

Understanding PCB assembly is the first step toward successful electronics manufacturing. Whether outsourcing or doing it in-house, paying attention to each phase of the process ensures your product functions as intended.