Exploring the Versatility of SiC Coating in Modern Industries

2025-01-15

As industries evolve, the demand for materials that can endure extreme conditions while maintaining performance grows. Silicon carbide (SiC) coating, with its superior properties, has become a go-to solution for a wide range of applications.

How SiC Coating Works

SiC coating is typically applied using advanced deposition methods such as:

1. Chemical Vapor Deposition (CVD): Produces uniform, high-purity coatings ideal for precision components.

2. Thermal Spray Coating: Used for applying thicker SiC layers in industrial applications.

3. Physical Vapor Deposition (PVD): Suitable for thin, hard coatings on smaller parts.

These methods ensure the coating adheres strongly to the substrate, offering long-lasting protection.

Industrial Applications of SiC Coating

1. Electronics Industry

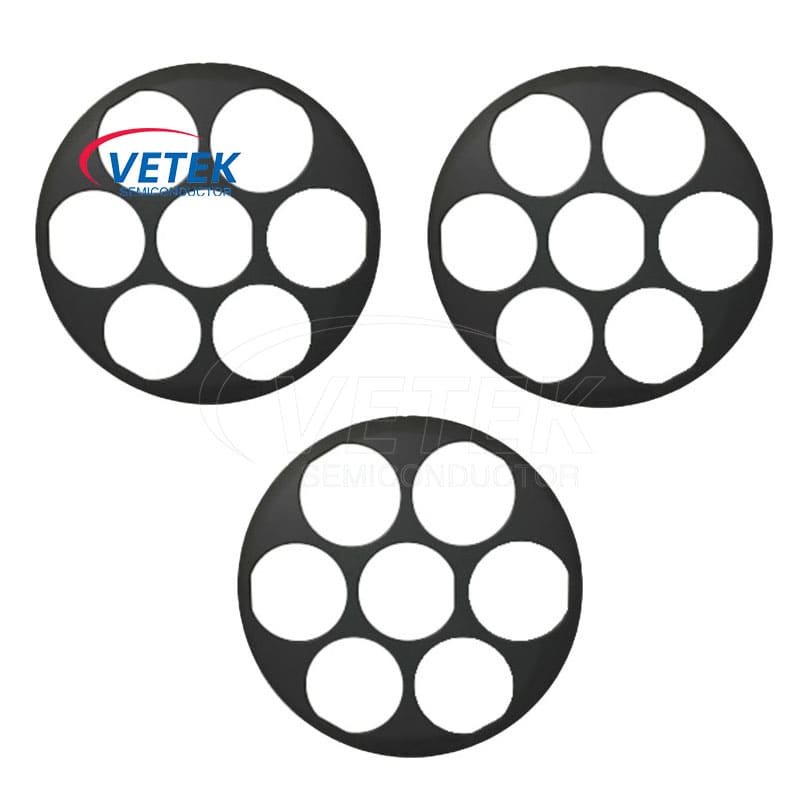

- SiC-coated wafers are essential for semiconductor devices.

- Provides insulation and thermal management in power electronics.

2. Energy Sector

- Used in solar panels and nuclear reactors due to its heat and radiation resistance.

- Protects components in renewable energy systems.

3. Manufacturing

- Extends the life of tools like cutting blades and molds by reducing wear.

- Enhances performance in harsh chemical processing environments.

4. Defense and Aerospace

- Offers heat and abrasion resistance for military-grade equipment.

- Protects spacecraft components from harsh space conditions.

Why SiC Coating Stands Out

- Sustainability: Increases energy efficiency and reduces waste by extending equipment life.

- Customizability: Can be tailored to specific applications by adjusting thickness and deposition methods.

- Safety: Provides a protective barrier against chemical exposure and extreme temperatures.

Challenges and Innovations

While SiC coatings offer significant benefits, challenges such as high production costs and complex application processes remain. Innovations in coating technologies, like the development of hybrid SiC materials and automated deposition systems, are addressing these issues, making SiC coatings more accessible.

Conclusion

Silicon carbide coating represents the future of material science, offering a combination of strength, efficiency, and resilience. Its versatility ensures its relevance across diverse industries, from advanced electronics to heavy-duty industrial applications. As technology advances, SiC coatings will likely play an even more significant role in shaping modern industry.