How to Choose the Right Carbon Steel Plate for Your Project

2024-12-21

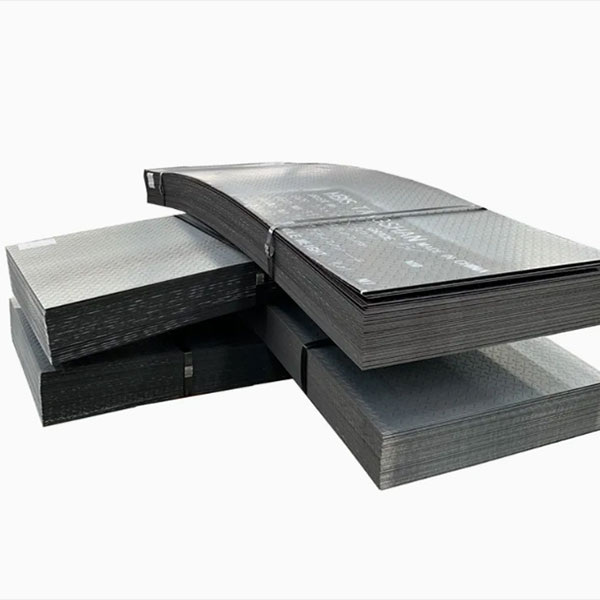

Selecting the right material is crucial for the success of any project, and carbon steel plates offer a range of options to meet diverse needs. In this blog, we’ll guide you through the factors to consider when choosing a carbon steel plate and why it remains a top choice across industries.

Why Carbon Steel Plates?

Carbon steel plates are favored for their combination of strength, flexibility, and affordability. Their ability to perform under various conditions makes them suitable for everything from construction to automotive applications.

Factors to Consider When Choosing a Carbon Steel Plate

1. Carbon Content

- Low-Carbon Plates: Ideal for applications requiring malleability and ease of welding.

- Medium-Carbon Plates: Suitable for structural applications needing a balance of strength and ductility.

- High-Carbon Plates: Best for parts subjected to high wear and tear, such as tools and machinery components.

2. Plate Thickness

- Thicker plates offer greater strength and durability, making them suitable for heavy-duty applications like shipbuilding or industrial machinery.

- Thinner plates are ideal for applications requiring lightweight yet strong materials.

3. Grade and Specification

- Ensure the plate meets industry standards (e.g., ASTM, EN) to guarantee quality and performance.

4. Surface Treatment

- Consider whether the plate requires additional treatments, such as galvanization, to enhance corrosion resistance.

5. Environment and Application

- For corrosive environments, opt for plates with coatings or treatments to prevent rust and degradation.

Common Uses of Carbon Steel Plates

1. Infrastructure Development

- Widely used in bridges, highways, and building frameworks for their strength and reliability.

2. Industrial Applications

- Essential for manufacturing heavy machinery, storage tanks, and pressure vessels.

3. Energy Production

- Utilized in power plants, oil rigs, and renewable energy structures for their durability and ability to handle extreme conditions.

4. Transportation

- Found in train cars, ship hulls, and automotive parts for their high load-bearing capacity.

Benefits of Choosing the Right Carbon Steel Plate

- Enhanced Performance: Ensures the material meets the specific demands of your project.

- Cost Savings: Prevents over-engineering by selecting the appropriate grade and thickness.

- Longevity: High-quality carbon steel plates withstand wear and tear, reducing maintenance costs.

- Safety: Provides the structural integrity required for critical applications.

Tips for Working with Carbon Steel Plates

- Partner with Reputable Suppliers: Choose suppliers known for providing certified and high-quality materials.

- Use Proper Tools and Techniques: Ensure precise cutting, welding, and shaping for optimal performance.

- Incorporate Surface Protection: Apply coatings or treatments to enhance the plate’s resistance to environmental factors.

Conclusion

Carbon steel plates are a cornerstone material in various industries, offering unmatched strength and adaptability. By considering factors like carbon content, thickness, and grade, you can select the perfect plate for your project’s needs. Whether you’re constructing a skyscraper or fabricating industrial equipment, carbon steel plates deliver reliability and value that stand the test of time.