What Are Conveyor Components ?

2025-09-04

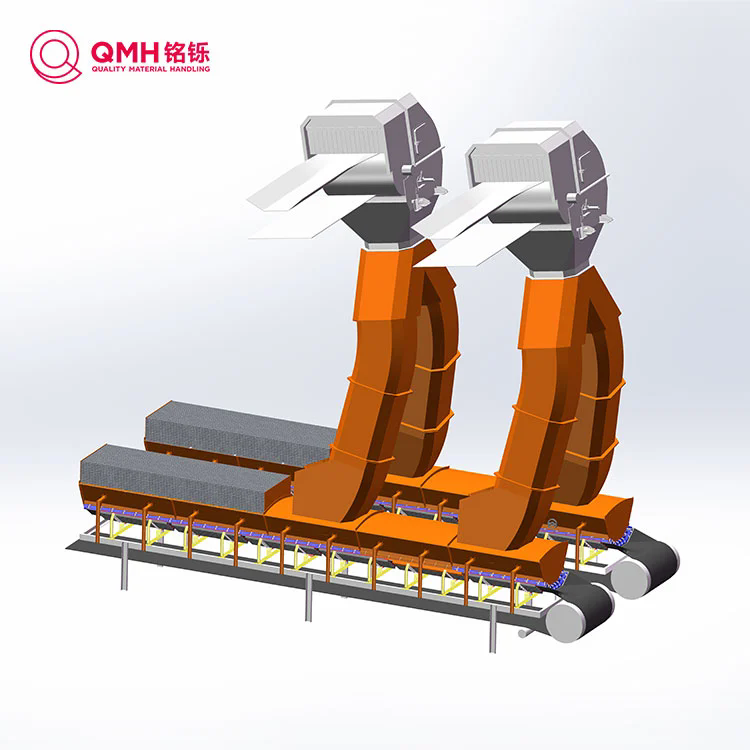

In today’s fast-paced industrial landscape, the efficiency of material handling systems plays a critical role in determining productivity, safety, and overall operational success. Conveyor systems are at the heart of most modern manufacturing and distribution processes, and at the core of these systems are conveyor components — the essential parts that ensure seamless movement, reliability, and reduced downtime.

What Are Conveyor Components and Why Do They Matter?

Conveyor components refer to the individual parts that make up a conveyor system, working together to facilitate the controlled movement of goods, materials, or products across a defined pathway. From rollers and bearings to belts and drives, these components ensure smooth operations in industries such as manufacturing, warehousing, logistics, mining, food processing, and e-commerce.

Importance of Conveyor Components in Modern Industries

-

Efficiency: High-quality components reduce friction, minimize stoppages, and maintain steady workflow.

-

Durability: Investing in premium materials lowers wear-and-tear costs and extends equipment life.

-

Safety: Well-designed parts prevent accidents, reduce system jams, and enhance operational safety.

-

Cost-Effectiveness: Using reliable components minimizes costly downtime and maintenance expenses.

-

Scalability: Systems built with modular components allow easy upgrades as your business grows.

Applications Across Multiple Industries

Conveyor components are widely used in:

-

Warehousing & Distribution Centers – Fast and accurate order fulfillment.

-

Manufacturing Plants – Streamlined assembly lines and product transfers.

-

Food & Beverage Industry – Hygienic, FDA-compliant conveyor systems.

-

Mining & Heavy Industries – Handling bulk materials under extreme conditions.

-

E-commerce & Retail – Ensuring smooth package sorting and delivery.

Understanding the role of these components helps businesses maximize output while maintaining safety and sustainability.

Types of Conveyor Components and Their Functions

Conveyor systems rely on a variety of components, each with a specific purpose. Selecting the right parts based on your operational requirements ensures peak performance and minimizes breakdowns.

Key Conveyor Components

| Component | Function | Material Options | Ideal Applications |

|---|---|---|---|

| Conveyor Rollers | Enable smooth movement of products along the conveyor path. | Steel, Stainless Steel, Plastic | Warehousing, Packaging, Mining |

| Conveyor Belts | Transport items between two points efficiently. | PVC, Rubber, PU, Fabric | Manufacturing, Food Processing |

| Conveyor Pulleys | Provide tension and direction control for conveyor belts. | Aluminum, Carbon Steel | Heavy-duty conveying, Mining |

| Bearings & Housings | Reduce friction and support roller movement. | Stainless Steel, Ceramic | High-speed and precision conveyors |

| Conveyor Frames | Provide structural support for conveyor assemblies. | Aluminum, Mild Steel | All conveyor setups |

| Conveyor Drives | Deliver power to move belts and rollers consistently. | Electric Motors, Gear Drives | High-capacity conveyor systems |

| Impact Beds & Bars | Absorb impact at loading points, protecting belts and structure. | High-Density Rubber, Polyurethane | Mining, Quarrying, Heavy Loads |

| Guides & Rails | Keep products aligned and prevent unwanted shifting. | Stainless Steel, HDPE | Packaging, E-commerce Sorting |

| Idlers | Support conveyor belts and manage tension. | Steel, Polymer | Bulk material handling |

Each component directly affects conveyor performance, so material selection and quality standards must align with operational demands.

Choosing the Right Materials

-

Stainless Steel: Ideal for hygienic environments like food processing.

-

Rubber & PU: Flexible and durable for heavy-duty or high-speed belts.

-

Polymer & Plastic: Lightweight and corrosion-resistant for e-commerce packaging.

-

Carbon Steel: Best suited for mining and bulk material transportation.

Best Practices for Long-Term Efficiency

-

Conduct regular inspections to identify early wear.

-

Use OEM-recommended lubricants to maintain performance.

-

Replace damaged parts immediately to avoid system-wide failures.

-

Keep a stock of critical spares to minimize downtime.

FAQs About Conveyor Components

Q1. What’s the difference between conveyor rollers and conveyor belts?

Answer: Conveyor rollers are cylindrical components that help move products by rotation and gravity, suitable for lightweight or gravity-fed systems. Conveyor belts, on the other hand, consist of continuous flexible belts that carry products using motorized drives, making them better for high-speed or inclined applications.

Q2. How do I know when to replace conveyor components?

Answer: You should replace components when you notice irregular noises, increased friction, unexpected vibrations, or decreased system efficiency. Visual inspections for cracks, rust, or belt fraying are also key indicators. Scheduling preventive maintenance checks ensures early detection and avoids costly unplanned downtime.

Enhance Your Conveyor System with QMH

Investing in the right conveyor components is essential for businesses aiming to maximize productivity, reduce downtime, and maintain safe operations. By understanding the different types of components, their functions, and how to select the right ones for your unique needs, you can build a more efficient and cost-effective material handling system.

QMH provides premium-quality conveyor components engineered for performance, durability, and seamless integration with your existing systems. Whether you’re upgrading a small warehouse or optimizing a large industrial plant, QMH delivers the solutions you need.

If you’re ready to enhance your material handling efficiency, contact us today to explore our full range of conveyor components and get personalized recommendations tailored to your business.